HACCP Quick-Start Guide

1. Assemble Your Team

Your HACCP plan shouldn’t be made in a rush or as a side activity. To make sure this doesn’t happen you should gather a team for constructing an effective HACCP plan. You should also make sure the team is made up of people with working knowledge of the process steps and operations that take place in your facility.

This would include people from manager level to the staff who work more directly with food preparation. But in case you run a small business, the team might even consist of just one person, usually the manager or other sufficiently experienced member of the staff.

However, even if you are the whole of your team, you should still make a note of who’s in it. Ultimately, this is a way of proving compliance as well as formally kickstarting the process of creating the HACCP plan.

In a larger company this also works as a signal for the employees on how serious you are about food safety and making sure it’s a priority in your business.

|

Psst!

|

2. Get Prerequisite Processes in Order

Now, a HACCP plan isn’t the end-all for your food safety program, and it isn’t the start-all either. Being able to create an effective HACCP plan requires you to already have other processes in use which support the success of your HACCP program.

These are known as prerequisites, and they are those safety and quality processes that are more general and applicable to almost any food businesses, whereas your HACCP plan is tailored to fit your product.

Prerequisite programs typically include such processes as:

• Good hygiene practices to prevent cross-contamination,

• Good storing/holding practices to prevent contamination by biological, chemical and physical hazards and to ensure the first-in-first-out principle is used.

• Allergen management program

• Cleaning and sanitation schedules and processes

• Equipment maintenance program

You should also have training program in place to help your staff follow these practices.

With all this done, you should find that many of the hazards you identify in the next stage are already pretty well under control.

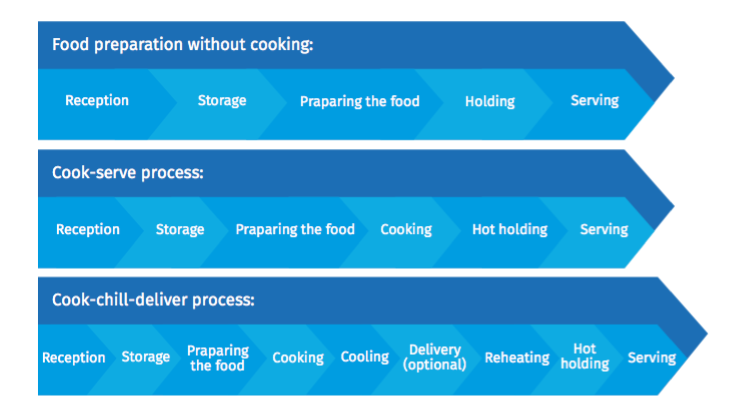

3. Map Your Process

No-one is a better expert on your process than you, so it’s difficult to give very specific advice to this step.

However, many kitchen operations tend to fit into one of a few basic structures, three of which you can find below.

Your individual process may have fewer steps, or include something not listed here. By identifying all the steps in your process, you’re set to start examining what kinds of hazards can be found in them.

4. Identify Potential Hazards

Having mapped your process, it’s time you took a hard look at where things can go wrong. That means evaluating every step in that process to see what kinds of hazards could conceivably occur there.

Typically, these food safety hazards are grouped into three categories: Biological hazards, physical hazards and chemical hazards. Any of these can cause your food to become unsafe for consumption. Let’s look a bit more into what these hazards might be.

|

Physical hazards Foreign physical matter entering your product Examples: broken off parts of equipment or packaging; pieces of clothing etc. Methods of control: Regular equipment maintenance, Good manufacturing practices, Detection devices |

|

Chemical hazards Chemicals that can contaminate exposed food Examples: Cleaning chemicals; maintenance products such as oils or greases Methods of control: Correct storage and cleaning practices |

|

Biological hazards Bacteria, viruses, parasites, fungi Examples: Salmonella, E. coli, mold Methods of control: Correct storage practices, Cooking to safe temperatures, Rapid cooling |

*This list is not comprehensive and only shows examples of hazards types and their control methods

So, go over your process and come up with different ways these hazards could enter it. You should also check if you have existing records of any food safety problems encountered previously, because they are provably something that can cause a risk in your process.

There are also checklists available for identifying hazards in certain kinds of processes, but following them meticulously from A to B shouldn’t be your end-all solution for hazard identification.

Remember, your hazard analysis needs to address, and be specific to, your process.

At this point you should list all potential hazards, even the smaller and less likely ones. This should yield a comprehensive list of all the ways in which hazards could be introduced into your process.

Now it’s time to assess the likelihood of those hazards happening, and the magnitude of the harm this can cause. You’re not expected to eliminate all hazards, just to control those that are reasonably likely to occur or can cause major harm to the health of consumers.

So concentrate on identifying relevant and realistic hazards, because next we’ll see what we can do to minimize the risk of them happening.

5. Manage Critical Control Points

Having come up with a list of reasonable hazards, it’s time to look at how to deal with them.

This is done by managing critical control points, or CCP for short. CCP’s are those steps in the process where control can be applied to eliminate, prevent or reduce hazards to an acceptable level.

Identify

Identifying CCP’s correctly is essential for effective food safety program, but it can also be a bit tricky.

Typically, only a few steps are critical and therefore absolutely essential for food safety. Not all steps where hazards could be controlled are CCP’s.

This is because if there’s a step later in the process where the same hazard is prevented or minimized, then the critical control point for that hazard is the later step.

Therefore, the comprehensive mapping and listing of hazards you made in the previous steps are a life-saver here. They allow you to easily track how individual hazards resurface in your process and pinpoint where the critical control points should be established for them.

Define critical limits and monitor them

One of the defining factors of a CCP is that it can be measured and there are science and evidence based critical limits within which the process is deemed acceptable.

Exceeding these limits is what risks food safety – and conversely keeping within these limits prevents hazards from endangering food safety.

Therefore, the next step in CCP management is establishing an effective monitoring program for these limits, so they don’t get exceeded.

This usually means either making observations (such as visually checking for mold or broken packaging) or taking measurements of different types.

Some of the more often used measurements in this context are:

• temperature measurements

• time

• moisture level

• pH

Setting limits for measurements is of course easier than doing the same for observations.

Setting some clear criteria for observation-based CCP’s is therefore very important. One way to support this could be to provide reference material such as visual aids in the form of pictures to help make the decisions easier.

Corrective actions

Of course, monitoring limits needs to be accompanied by an established process of what to do if they are exceeded.

Therefore, you also need to prepare preventive actions that can be taken if any of your CCP’s goes out of established limits. Training your staff to know which actions to take and how to do it is also essential.

This is arguably the most important part of the whole HACCP program, because it enables you to take actions to safeguard your food safety and prevent risk to consumers. And naturally it also helps you eliminate disruptions to your business and prevent potential brand damage.

Concretely, an example of CCP monitoring and corrective actions might be monitoring your cooking temperatures to make sure you’re heating your ingredients hot and long enough to kill harmful bacteria.

And if your thermometer then shows something hasn’t been heated enough, the corrective action would be to heat it more until it is safe to eat.

As you can see, both the critical limits and corrective actions are usually something you’re probably already handling pretty well.

The HACCP plan just allows you to manage all this in a more systematic way.

6. Keep Records

A big part of HACCP and food safety compliance overall is keeping records of the program and relevant activities.

These include the HACCP plan itself, as well as the records of monitoring critical limits in the process.

It should also hold information on what corrective actions to take, which corrective actions have been taken during the process as a consequence of exceeded limits and other pertinent maintenance, calibration etc. records.

You could also include records of your verification activities and whether those have resulted in any changes or modifications (although these of course also go into the HACCP plan itself).

All this can become laborious, however, especially if you need to revise and disseminate those revisions to multiple locations even relatively often.

To counter this, you should aim to simplify your record keeping as much as possible so that it doesn’t consume too much of your staff’s time which could be used more productively elsewhere.

7. Verify and Reiterate

Having drawn up a HACCP plan with all critical control points identified, monitored and managed, the next thing is verifying your system is working as it’s supposed to do.

The verification should be conducted by someone not directly involved in performing HACCP activities, but this is again dependent on the size of your business.

Usually this involves a member of the management verifying that the staff is performing all the checks they are meant to; that all equipment are working and calibrated; reviewing monitoring records; and other such measures.

It can also help to discuss the HACCP process with employees at this point as well, as they can have a more focused view of performance in specific segments of the process.

This has the additional benefit of involving your whole staff more in your food safety program, which in turn can help build an overall culture of food safety in your company and improve food safety and quality in an organic way.

|

Psst! If you want to do something more extensive than an internal verification, independent HACCP consulting services are also available to help with this – and they can also be used to help draw up the plan in the first place |

Sometimes a periodic verification can also lead to you having to modify or improve your HACCP plan when you notice something is not controlled to the level it should be.

And remember: you should also revise your plan every time the process changes and verify the effectivity of any new measures just like you do with the existing processes.

In this way your HACCP plan can grow to be more effective iteration by iteration.

Benefits of an HACCP Food Safety Program

So finally we arrive here, and now with a much better understanding of what setting up a n HACCP program would entail.

The obvious question now is what you then get by adopting this kind of approach to ensuring your food safety?

And the obvious answer is safer food, but that’s not all there is to this particular program.

Having worked with many kinds of HACCP use cases over the years, we’ve seen those businesses that adopt the method gaining several additional benefits along with better food safety.

Some of these are, in no particular order:

• Less product loss

• Improved and more consistent product quality

• Better food safety culture overall with increased staff involvement

• Increased profits

Upgrade to Digital Food Safety & Quality Management

But what if this kind of food safety program sounds like a whole lot of work, even after looking at the benefits? Well, there is an easier way for you to go forward.

By upgrading their HACCP program management with Sensire’s digital HACCP system, food businesses are able to bundle their HACCP program and prerequisite processes into one comprehensive yet simple-to-use food safety management solution. This has offered them a host of new capabilities and benefits like:

• Training new staff easily using digital guidance for task performance

• Supporting staff success with task scheduling and directions

• Eliminating emerging risks with guided corrective actions

• Reducing risks and waste with automatic temperature monitoring

• Gathering and monitoring data from all locations for effective analysis

• Ensuring compliance with transparent reporting

Should you want to hear more about digital food safety management, we are always happy to help in any way we can.