Recently the European Commission has published new guidelines for food safety management systems (FSMS) that aim to support small businesses in implementing EU regulations to ensure safe production and handling of food to be distributed to customers.

This new approach is based on clear flowcharts that summarize the individual steps in production as well as simple tables that guide small business owners through the entire process of ensuring food safety – from hazard identification to corrective measures. The provided information is in accordance with existing legal requirements and can be adapted by food businesses to their specific activities.

The guidelines were drawn up with the participation and consultation of various experts from the member states. They take into account some practical experience from countries that already apply the recommendations. The EU Commission further points out that the guidelines are legally non-binding and that there may be additional national requirements which must be considered on a case by case basis.

The document is quite remarkable as it addresses specific issues and offers concrete assistance for the respective companies. For this reason, the guidelines are of particular importance for the concerned businesses.

HACCP and other practices

Securing optimal food safety is of utmost importance, no matter if it’s at home, in restaurants, commercial kitchens or catering. One must be mindful of the consequences of how food is handled before, during and after preparing – as all stages are equally important. Foodborne illnesses are a thing and consuming contaminated food can lead to possibly easily avoidable outcomes, if proper training and safety measures are followed.

The European Union, as well as many other countries all over the world, requires food businesses to comply with a hygiene requirements revolving around procedures based on the Hazard Analysis and Critical Control Point (HACCP) Principles. Goal is to effectively prevent hazards from biological, chemical, physical and allergenic risks in all phases of a food’s life cycle – from raw materials to consumption.

HACCP procedures are usually accompanied by several prerequisite programs, preventive practices and conditions that are essential for food safety: e.g. Good Manufacturing Practices (GMP), Good Hygiene Practices (GHP), Good Production Practices (GPP) or Good Distribution Practices (GDP).

Together with other known standards and practices concerning food safety, like ISO 22000, the Safe Quality Food Institute’s SQF Code, ISO 9001, HACCP is often seen as a burden to adopt and manage – especially for small food businesses without the manpower or expertise.

Small Business: Simplified Food Safety Management

The nature and size of a food business must be taken into account when verifying compliance with the procedures based on the HACCP principles. The guideline specifically mentions the following small businesses as targets for a more flexible approach to applying food safety management systems: butcher, grocery, bakery, fish and ice cream shops, distribution centers, supermarkets, restaurants, catering services and pubs.

It has been recognized that for certain food businesses it is not possible or feasible to identify and monitor critical control points as part of a full-fledged HACCP program. In some cases, good hygiene practices and prerequisite programs can replace these procedures.

That means that a small business does not necessarily need to have in-depth knowledge of each hazard, but it’s enough to be aware of the general hazard groups (biological, chemical, physical or allergens) that may emerge during processing the food.

It further is enough to understand that neglecting to do certain risk-reducing activities, like separating raw and ready-to-eat foods presents a risk. But there is not requirement to additionally understand or apply risk ranking.

5 steps for a simplified FSMS approach in small businesses

-

- Awareness of hazard groups without in-depth knowledge of specific hazards

- Failure to perform risk reducing activities constitutes a risk

- No requirement to understand or apply risk ranking

- Allergens are treated as a separate hazard

- PRPs must always be in place and can be sufficient

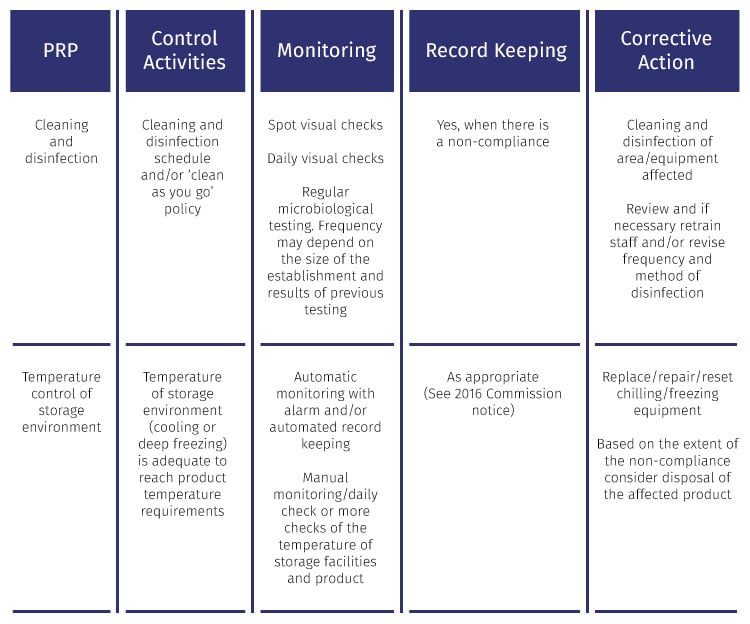

The guideline offers pre-filled flow diagrams according to generic hazard analysis tables that can be used in a modified or unmodified way after doing a hazard analysis of the respective business. Additionally, the document lists 13 relevant Prerequisite Programs (PRPs) for ensuring food safety.

The PRP table provides guidance on how hazards can be controlled and how monitoring, record keeping or corrective actions can be facilitated. For demonstration purposes, we will show an excerpt of the recommendations.

Proper cleaning and disinfection procedures are especially nowadays more important than ever. Excellent hygiene practices are more often than not attractive for returning as well as new customers. Further, the undisturbed operation of refrigerators and hot-holding equipment is paramount for food safety. You don’t want to enter the temperature danger zone!

Manual vs. Automatic - Did someone say digital?

Whether your business is using a full-fledged or simplified version of these food safety managing systems, if you are choosing the manual path for documentation, you are missing out.

Endless checklists, record keeping, monitoring results and reporting create mountains of paper, stacked into boxes, stashed somewhere on the premises or your home. They are amounting to mostly mountains but won’t help you advance your business.

With a complete digital management solution for food safety and your business, you can streamline the whole process of checklists, tasks, monitoring and reporting. We believe that compliance should be easy and not a burden to you or anyone else involved in food safety.

You could access all your data through a handy online dashboard, where the necessary information from automatic temperature sensors, Bluetooth probes and completed tasks through the mobile app are compiled.

Check out our guide on digital HACCP for a better understanding of our solution and what is possible if you go digital.

***

If you have any questions, want to see how we might be able to help you in digitalizing your food safety management or HACCP and quality processes, please get in touch with us.