Quality Managers (QMs) in the Food and Beverage manufacturing industry play a pivotal role in ensuring that products meet the highest standards of quality, safety, and compliance. In today's rapidly evolving landscape, QMs are facing a multitude of challenges and opportunities. Let's delve into the key trends that are shaping the industry and how Quality Managers can navigate this dynamic environment.

1. Innovative Processes, Products, and Packaging

The food and beverage industry is no stranger to innovation. From high-pressure processing (HPP) for natural applications to cutting-edge packaging solutions, innovation is driving consumer demand. As a Quality Manager, embracing these innovative techniques is essential to stay competitive while maintaining product quality and safety. One important balancing act is supporting the process efficiency and tasks without compromising quality.

2. Sustainability and Waste Reduction

Sustainability is no longer a buzzword; it's a consumer-driven movement. QMs are instrumental in implementing sustainable practices, reducing waste, transitioning from nonchalant waste creation, and handling raw materials. Some industry leaders, like Unilever, have repurposed production line leftovers, setting an example for reducing waste in manufacturing. The absolute first step for tackling waste is tracking waste, something many QMs look to do with the help of digitalization, smart task management, and analytics.

3. Automation and Labor Shortages

Labor shortages are a reality. Quality Managers must explore the integration of technology in various processes, ensuring that quality control remains at the forefront as the industry adapts to these changes. Another possibility and necessity are ensuring new employees with little or no background in work relating to Food and Beverages is ensuring that trainings, instructions, and measurements/feedbacks are offered in multiple languages and in accessible forms like images and videos. Especially new employees and resources from employee rental companies need to be supported, and all completed tasks from receiving inspections to shipments to clients need to be documented and searchable.

4. Supply Chain Challenges

The food and beverage industry's supply chain is under pressure from shifting consumer habits and raw material shortages. Efficiency and speed of transport are paramount. As a Quality Manager, working closely with supply chain partners and adopting digital solutions can mitigate these challenges. Many QM:s need better information about deliveries, from correct order amounts to raw material conditions, preferring quality management systems that support images and comments directly from the receiving inspections.

5. Regulatory Compliance and Food Safety

Governments worldwide are tightening regulations on food safety. As a Quality Manager, keeping abreast of these changes is crucial to ensure compliance. The first step is to log information, and the second step is to have easy access to data. When QM:s can easily select critical data for ensuring and proving compliance, a big chunk of unnecessary work disappears from the busy agenda.

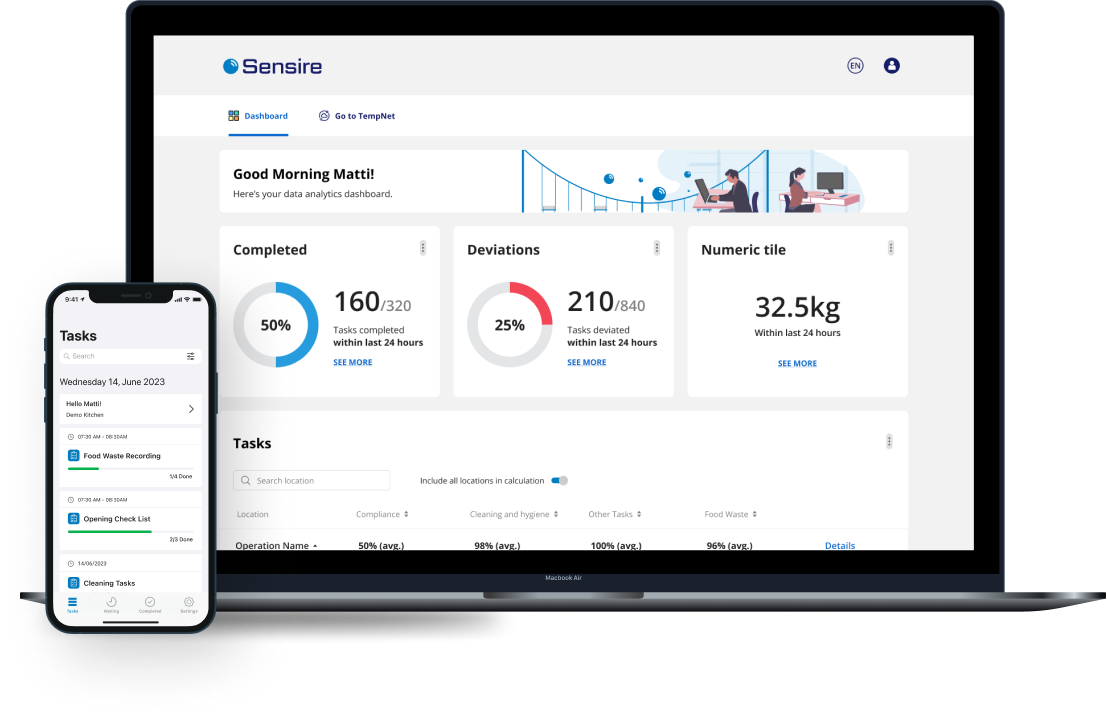

6. Technology Integration

The integration of technologies around quality, task management, and documentation is transforming the industry. These technologies enhance audits, provide predictive analytics, show "black spots" in production, includes quality control across multi-locations and lets QM:s focus on strategic improvements. Quality Managers should explore how these tools can optimize their processes.

7. Predictive Quality Management

Leading companies are shifting from reactive to preventative, and ultimately to predictive quality management. Cloud-based solutions are enabling QMs to anticipate issues, ensuring product quality and safety proactively.

8. Changing Regulations

Balancing innovation with regulatory compliance can be challenging. Quality Managers must assess the risks associated with novel foods, health claims, and e-commerce while ensuring product safety and adherence to standards.

9. Quality Management Systems

Implementing robust Quality Management Systems (QMS) is crucial. These systems streamline business processes, mitigate quality issues, and reduce product waste. QMs should focus on maintaining consistency and meeting quality and compliance standards. As many QM:s work closely with their Production Manager colleagues, a good QM system should be easy to use for the employees, yet offer enough modern technology to be able to send and manage information to production systems and factory systems.

Conclusion

Quality Managers in the Food and Beverage industry are navigating a complex landscape filled with innovation, sustainability demands, and regulatory challenges. Embracing technology, automation, and sustainable practices while maintaining a strong focus on quality and safety is essential for success. By staying informed and adaptable, Quality Managers can lead their organizations to meet evolving consumer preferences and industry standards in this dynamic era of food manufacturing.