Food safety processes are never perfect, and zero risk is not possible when it comes to food safety, no matter how hard consumers, industry and governments try. With countless moving parts and processes, nonconformity is bound to happen during daily food production and preparation.

Avoiding the financial and reputational damage caused by food recalls or food safety issues makes prioritizing food safety a no-brainer.

Food safety technology and automation can facilitate this process, making conformity, documentation and analysis easy and efficient. With food safety under control, you will be able to maintain quality and brand image.

Improving Efficiency with Digital Food Safety Technology

By automating your food safety processes, you will be able to increase the efficiency of your operations and monitor quality more effectively. Plus, by increasing productivity in terms of food safety, you can increase your bottom line.

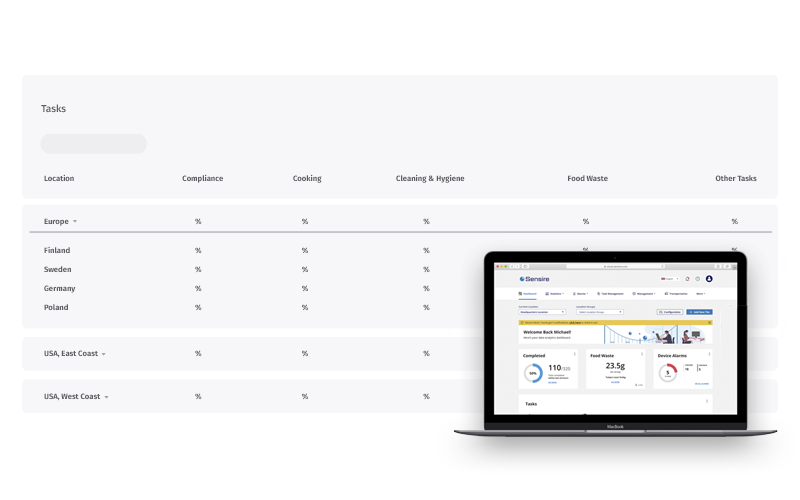

Digital food safety technology works at single-site operations, like a small restaurant, and it can be easily scaled to multiple locations or larger operations, like Quick-Service-Restaurants (QSR), food chains or factory-level food production.

Data mining and data-usage has become an integral part of almost all business divisions. Digital solutions allow you to collect and analyze huge amounts of data to be used for improving overall food production, handling processes and ultimately your entire business.

Automating Manual Processes

Food safety regulations require you to follow the regulations and document all of your processes closely. This can be time consuming and that’s where automating your food safety processes can do a great deal to help.

Automating your food safety management allows for full traceability and increased awareness of issues. It also helps to ensure you are truly fulfilling all of the necessary regulations. Intelligent monitoring techniques, e.g., automatic temperature sensors, help to track conditions in your facilities and basically control the environments in real-time.

Manual monitoring processes are usually associated with a higher error rate, and they delay the speed with which one is able to identify and solve problems and prevent further ramifications. Relying on inconvenient and inefficient spreadsheets, emails or paper files to track food safety related tasks, can be inefficient and costly.

Leveraging Your Data

One key thing to remember is to leverage your data. Using a paper-based documentation system makes data analysis quite difficult, but with digital food safety solutions, you can collect all kinds of data, all the time.

Still, it's important to leverage the data you’re collecting, and use it to identify areas for improvement in your food safety processes and performance tracking. By leveraging your data, you will be able to reduce downtime and perform necessary inspections while increasing overall food production efficiency as well as quality.

Digital solutions can provide all necessary information to users across locations with the push of a button and even inform them of non-compliances automatically via alerts.

Automating food safety technology empowers a continuous improvement process, including management of data and communication between divisions. It lets you approach the topic more proactively, helping you to identify trends and emerging problems. Plus, since manual input is minimized, managing and maintaining your data in the cloud keeps you audit ready at all times.

Prevention with Digital Food Safety Technology

Digital food safety helps to address quality issues before they become a real issue by making sure that food safety best practices are followed every step of the way, thus saving the company money as well as protecting its image.

Monitoring solutions with real-time visibility give unique insight into the food production processes, reducing the risk of non-compliances and protecting consumers from foodborne illnesses.

Unplanned downtimes are a major disruptor in food businesses. Proactive, predictive maintenance with the use of intelligent monitoring solutions reduces the risk of such unplanned downtime immensely. Being able to react quickly to a broken fridge or oven is key to prevent more food waste, protect profits and keep customers happy.

***

Sensire offers you the most comprehensive digital quality and compliance management solution, providing you with the tools you need to run your business effectively. Our fully adjustable system gives you the unique visibility of your processes that you’ve always wanted. If you have any questions or want to see a live demonstration, feel free to contact us directly.