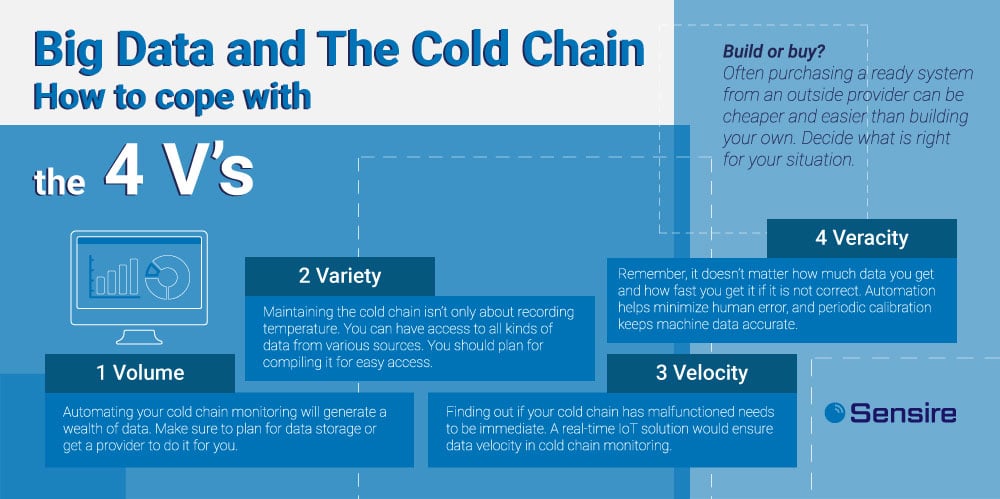

A few weeks ago I wrote an article on LinkedIn about the questions people should ask before implementing the Internet of Things (IoT) into their operations. In it I asked people to think about where the expected return on investment (ROI) would come from with this new system. This time I’ll look at four aspects of IoT data needed to deliver both the initial ROI as well as additional benefits. I’ll do this by looking at volume, variety, velocity and veracity of data (collectively known as the “4 V's”) in the context of IoT in the cold chain.

1. Volume

The whole thing about IoT is that it does not rest. That means there is a constant flood of data coming your way. You'll have to find a way to stay afloat or you’ll drown in it. One way is to learn how to swim, which means you do all the work yourself. If you have a sizeable IT department with data analytics capabilities this might be feasible. For others it will be easier to invest in flotation devices, i.e. data analytics and visualization tools.

"You'll have to find a way to stay afloat or you’ll drown in data."

Either way, with IoT you’ll be collecting tons of data. Don’t throw that away. If your industry is very regulated, you should store it at the very least for compliance reasons. But more than that, you should do it to improve your operations. Analyzing a massive pool of real-life data and especially seeing it in visual form makes it much easier to find beneficial trends to base process optimization on. If that is your goal, then data volume is going to be your best friend.

For example, a cold storage operator whose facilities run colder than needed will be paying bigger electricity bills for no good reason. If you think about every extra degree as two percent of electricity expenses, being able to act on this information promises big savings.

2. Variety

But it’s not all about the amount of data. Imagine you won free ice cream for the rest of your life, delivered to your home at the start of every week. Every Monday morning you would open your front door to receive a tub of vanilla ice cream. After a few weeks or months you’re bound to get fed up. But what if every week brought you a new and unexpected variety?

Now, from a cold chain perspective, even if you only monitor temperature, there’s lots of data you produce on the side. For a freight company dealing with cold transports this could be the departure and arrival times of cargo, which are recorded as the temperature monitoring turns on and off. This helps ascertain transportation times and affects route optimization. If they were also collecting GPS data, they could straight away see where any challenging parts of the route lie and then steer away from those.

"Imagine you won free ice cream for the rest of your life. Wouldn't you get fed up if it was always the same flavour?"

Or in a cold storage facility this might mean automatic recording of staff response times to temperature exception. The additional data can easily used in monitoring and improving operational efficiency.

Either of the hypothetical operators in the previous examples wouldn’t likely have calculated these into their concrete ROI expectation. But when all this various data is compiled into one place the connections will be easy to see, even when no-one will have thought to look for them before.

3. Velocity

One of the best things about IoT-produced big data is that you can get it in real time. At the most basic level data velocity means immediate action if something goes wrong.

So if you calculate getting ROI by minimizing waste in the cold chain, velocity is what gets you there. For example, if your truck has a problem with its refrigeration unit, the driver gets alerted and knows to call a functioning replacement or drive to a closer cold hub. Without data velocity he’d happily keep going while the shipment melts and spoils.

"Without data velocity you won't know it if your cold chain shipment melts and spoils."

But getting immediate real-time data isn’t just about corrective actions. Having access to information on what is happening right now helps turn that into predictive or even prescriptive analytics. Then the data doesn’t only tell you what has happened or is happening. It also tells you what is likely to happen and what to do about it.

To take the greatest advantage of predictive and prescriptive analytics, you can introduce machine learning or artificial intelligence into the process. Or if you don’t want to do that yet, it’s undoubtedly a likely direction technology will take and with real-time data you’re well poised to adopt AI when the time is ready.

4. Veracity

The most important thing in this blog is this: if your data is wrong it doesn’t matter how much of it you get or how fast you collect it. So how to make sure you are collecting accurate data? There are two main ways, namely automation and calibration.

The importance of calibration is easy to understand, because you can only get accurate readings when your instruments can deliver them. You can be lulled into a false sense of security when you purchase electronics and assume they will perform perfectly as long as they’re working. But if you really want to keep your data ticking correctly, you’ll need to take care of calibrating any sensors, preferably annually. Consider it this way: your devices will only keep you as safe as you keep them.

"If your data is wrong it doesn’t matter how much or fast you collect it."

Automation, on the other hand, is about people more than technology. Automation in itself doesn’t turn the collected data into any more accurate than what is measured. The correction here is about human error. Even messy handwriting or forgetting to note down a specific number risk expensive consequences. Automating the measuring and sending of data is one of the simpler ways of making sure the data you see reflects reality.

Obviously you can see how I’ve treated everything above like data veracity was ensured. This is easier said than done, so you really should ascertain your data is telling the truth. Making decisions based on incorrect information is likely to only compound any problems you might have.

Monitoring as a Service

In the previous article I also wrote about IoT implementation as a decision between building your own or buying a ready solution from a third-party vendor. Looking now at the 4 V’s here, I’d say there’s definite advantage to purchasing IoT monitoring as a service.

Actually, it’s not unlike building a house: for some people that is the best way to get just the kind of home they’re looking for. For most of us, though, we’ll be just as happy with buying something that checks all the boxes for our needs.

"Building your own IoT system isn't impossible, but it isn't simple either."

Look at it this way: if you start building your own monitoring system from a scratch, it’s quite easy to get volume, because that is only about connecting things to the internet. Reliability will be tougher to achieve. Adding more measurements will make building or finding adequate devices harder still.

I’m not saying building an IoT system isn’t doable. It verifiably is, we’ve done it ourselves. What I am saying is that even with our team of dedicated professionals, it wasn’t as simple as just deciding to do it. And knowing that, I’m very confident when I say that unless you really are one of the few cases where building your own system is a walk in the park, it’s just easier to get your system ready-made by a specialist.