Protecting People and Products

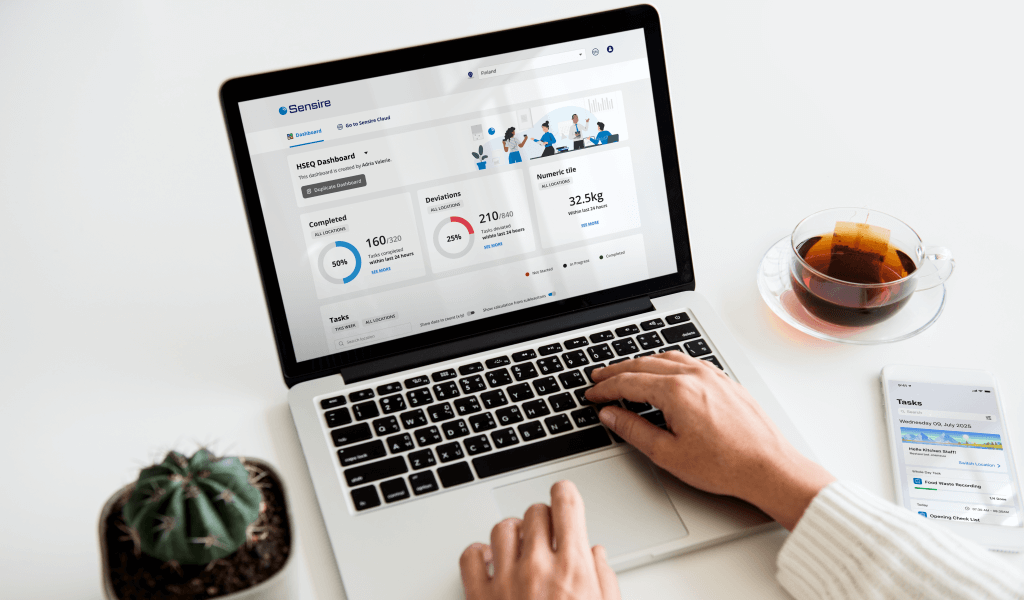

Smart HSEQ Solutions for Workplace Safety & Quality Management

HEALTHCARE & PHARMACEUTICALS | FOOD & HOSPITALITY |

LOGISTICS & WAREHOUSING | SOCIAL, PUBLIC & EDUCATIONAL SERVICES |

RETAIL & SHOPPING CENTERS

We make sure everything is as it should be, so you can focus on what matters

Digitalized Product Safety

We optimize your product safety, quality control & operational efficiency through automated condition monitoring and digital task management.

Temperature & Condition Monitoring

Real-time condition monitoring handles the work for you, while automated exception alerts ensure product safety throughout the supply chain.

Workplace Safety

We provide reliable safety solutions for any environment — indoors, outdoors, or on the move. Staff can send quick, discreet alerts with precise location data, ensuring responders act instantly and effectively in any emergency.

Lone Worker Protection

Ensure the safety of employees working solo — whether in warehouses or on the road — by sending immediate alerts with their precise location when emergencies occur.

Warning Solutions

Instant warning alerts on every screen ensure staff safety. Messages are clear and impossible to miss when seconds matter.

Task Management & Compliance

We ensure that everything is done correctly across your locations while simplifying compliance and report generation.

Document Management

A centralized repository for storing, modifying, and managing relevant documents, based on user permissions.

Energy Monitoring

Our easily integrable solution monitors energy consumption, detects usage spikes, and helps you operate cost-effectively and sustainably.

Tailored solutions for your industry

Healthcare & Pharmaceuticals

The smartest solutions for cold chain monitoring, task management and staff safety for pharmacies, pharmaceutical warehouses, and hospitals.

Food & Hospitality

Our modern HACCP, temperature monitoring, and safety solutions meet the needs of the food industry, professional kitchens, hotels, and restaurants.

Retail & Shopping Centers

We keep employees safe with modern alarm technology and the support services for security staff. Product safety is ensured through comprehensive quality management and condition monitoring systems.

Logistics & Warehousing

Automated, high-quality condition monitoring for supply chain and reliable lone worker protection for warehouses and transportation.

Social, Public & Educational Services

First-rate solutions for staff safety, mass warning and product quality control across care homes, schools, citizen and job centers, and more.

The smartest solutions for cold chain monitoring, task management and staff safety for pharmacies, pharmaceutical warehouses, and hospitals.

Our modern HACCP, temperature monitoring, and safety solutions meet the needs of the food industry, professional kitchens, hotels, and restaurants.

We keep employees safe with modern alarm technology and the support services for security staff. Product safety is ensured through comprehensive quality management and condition monitoring systems.

Automated, high-quality condition monitoring for supply chain and reliable lone worker protection for warehouses and transportation.

First-rate solutions for staff safety, mass warning and product quality control across care homes, schools, citizen and job centers, and more.

Key Questions about Sensire

What services does Sensire offer?

Sensire provides digital HSEQ, quality management, temperature monitoring and workplace safety solutions that help organizations ensure the safety of both products and employees through a centralized platform.

Who is Sensire designed for?

Sensire is designed for organizations in healthcare, laboratories, food & professional kitchens, and public sector environments where safety, quality management and compliance are critical.

What problems does Sensire solve?

Sensire helps organizations prevent serious and costly incidents by continuously and automatically monitoring critical conditions and operational tasks. Sensire enables early detection of risks, ensuring product quality and employee safety before problems escalate.

Our full-service solutions include everything from a first-class applications

to high-quality customer support

Easy to use

- Implementation is extremely fast, and once set up, our solutions and devices are simple and effortless for every employee to use.

Scalable

- Guarantee uniform guidelines and procedures across all your locations.

- Ensures product and staff safety in every location and in changing environments.

Reliable

- Always dependable, our solutions and devices safeguard both employees and products without ever letting you down.

- With over 20 years of experience in the HSEQ field, we ensure confidence in safety and regulatory compliance.

We are expanding our offering with

WORKPLACE SAFETY & LONE WORKER PROTECTION

Comprehensive safety solutions for employees, security personnel,

and lone workers to ensure protection across diverse environments.

Explore our new solutions!

HSEQ is a framework for managing health, safety, environment, and quality. It is widely used in industries like food services, manufacturing, healthcare, and social services to ensure compliance, product safety, and operational excellence.

"Blood transportation requires 100 % controlled conditions. With all data accessible in the Sensire Cloud, it has become easy to recognize problem hotspots, leading to less waste."

/Sensire%20Website/Logos/Logo_color/spr-eng_crop.png?width=213&height=60&name=spr-eng_crop.png)

Ari Hemminki, Production Manager, FRC Blood Service

Our centralized approach enables systematic monitoring, quality improvement & staff protection

With over 20 years of experience, we've dedicated ourselves to providing solutions that address your specific needs.

Ensures a safe working environment

Improves job satisfaction

Keeps tasks on track

Reduces costs effectively

Reduces waste

Makes day-to-day work easier

Standardizes procedures

Optimizes time management

Ready to take your product quality & workplace safety to the next level?

Join hundreds of successful operations to achieve their business goals with our solution!